KITZ stainless and high alloy steel valves are widely utilized in Chemical, Petrochemical, food and beverage, pulp and paper, Pharmaceutical and other industrial processing plant through the world.

- Product Service TOP

- List of Products and Services

- Gate, Globe, Check Valves and Strainer

- Gate Valves

- Stainless & high alloy steel valves

Stainless & high alloy steel valves

Corrosion Resistance of KITZ Stainless and High Alloy Steel Valves

KITZ stainless and high alloy steel valves are designed, manufactured, and inspected to strictly conform with the requirements of ASTM, ASME, API, BS, JIS and other internationally recognized standards, with all quality elements meeting the critical service conditions needed for corrosive industrial applications.

KITZ stainless and high alloy steel valves are characterized by unsurpassed corrosion resistance and reliability, providing users with the lowest cost of ownership and the longest total life cycle performance in the industry. As an ISO 9001 certified valve manufacturer, KITZ Corporation has achieved a high degree of product standardization by the ideal combination of its updated technical know-how and uniquely integrated system of production adopted at its Nagasaka Plant, Yamanashi, Japan, the home of KITZ stainless and high alloy steel valves.

Electronically controlled steel foundries, multi-station transfer machining systems and state-of-the-art test and inspection facilities, are all put together at KITZ Nagasaka Plant, to ensure the quality and reliability of all products that it releases to the global market.

Features of Austenitic Stainless Steel as Valve Material

Stainless steel is divided into three main categories depending on its chemical composition. They are martensitic stainless steel containing 13% chromium, ferritic stainless steel containing 18% chromium, and austenitic stainless steel containing 18% chromium and 8% nickel. Among them, austenitic stainless steel is widely used for both valve shells and trims, which require high pressure resistant characteristic. Martensitic stainless steel is used mainly for trims of carbon steel valves. The features and characteristics of these stainless steels are compared below:

Features of Stainless Steel by Types

| Types | Martensitic | Ferritic | Austenitic |

|---|---|---|---|

| Typical Material | AISI 410 | AISI 430 | ASTM CF8M/F316 |

| Magnetization | Yes | No | |

| Hardening by heat treatment | Yes | No | |

| Hardening by machining | Same as soft steel | Less | |

| Corrosion and acid resistance | Good | Excellent | |

| Impact resistance and elongation | Good | Excellent | |

| Weldability | Poor | Fair | Good |

| Lowest service temperature | -29°C | -10°C | -269°C |

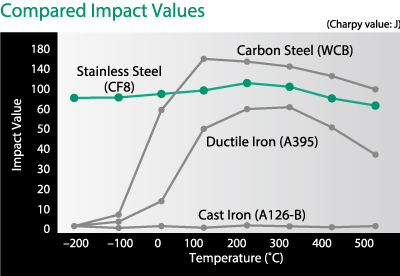

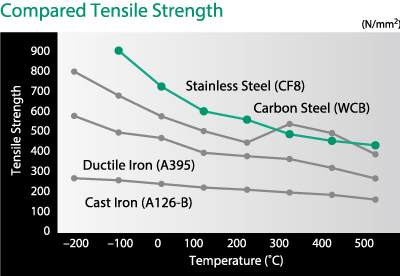

As shown below, austenitic stainless steel has an excellent impact value in subzero temperature range and been almost exclusively used for cryogenic service applications. It also features higher heat resistance than carbon steel. Its tensile strength is also superior to other valve materials and its high resistance against destructive tensile load in a wide range of service temperatures is unrivaled by other valve materials. Corrosive fluid cannot generally affect these excellent mechanical properties of austenitic stainless steel.

On the other hand, austenitic stainless steel is known as a very mild metal having no effect on the quality of the materials it comes into contact with. Line fluid is not contaminated while traveling through austenitic stainless steel pipelines. This advantages makes austenitic stainless steel valves the important fluid handling media for food, beverage and pharmaceutical processing plants. In addition, austenitic stainless steel CF8M or F316 has higher resistance to sea water erosion and is widely used for the valves installed in seawater disalination plants, offshore exploration facilities and ocean structures.

This catalog introduces manual valves.

Bellows valve

The gland section is protected by a double seal of molded bellows and gland packing, so there is no external leakage.

- No stem leakage

The stem area is sealed double with a formed multi-ply bellows and gland packing, which completely prevent stem leakage of toxic fluids.

- Saving manufacturing costs

No loss of the line fluid through stem area will increase your productivity.

- Wide range of applications

With high corrosion resistant valve bodies made of austenitic stainless steel and leak-free stem design, valves are almighty to handle toxic or inflammable fluids, steam and heat transfer media, as well as vacuum service.

- Easy maintenance

Gland retightening and packing replacement are not required, minimizing troublesome maintenance works.

- Protection of the quality of line fluids

Fluids are not in direct contact with an atmosphere, and protected from the contamination caused by foreign objects.

- Lower operation torque

Since gland retightening is not required, stem rotation is not disturbed with the load of gland packing. Thus valves can be operated with minimized torque.

Cautions

- Take appropriate preventive measures when freezing is expected.

- Protect valves from impact pressure, such as water hammer.

- DO NOT install valves where excessive vibration is expected.

- Take appropriate measures to protect bellows from highly viscous or solidifiable fluids.

Registering E-mail Magazine

We will send support information, new product information, and application information for our users.