A sharp lambda-shaped edged disc, combined with a metal seat, cuts through all impurities suspended in the line fluid when the valve is closed and has additional applications for throttling (regulating flow volumes at an intermediate travel). Lambda port valves are ideal for the control and shutoff of slurries, highly viscous fluids and fibrous fluids such as pulp and paper material.

- Product Service TOP

- List of Products and Services

- Butterfly Valves and Ball Valves

- Λ port ball valve

Λ port ball valve

DESIGN FEATURE

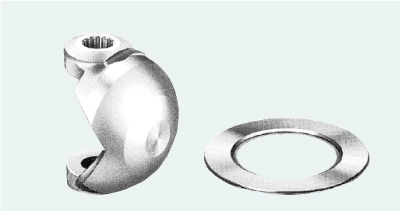

1. Sharp solid cutting

A trunnion mounted disc is sharply edged for cutting solids and fibrous objects mixed in line fluids, preventing disturbance to valve closing operation, and minimizing fluid residue within the valve bore.

2. Choice of trims

Choice of two different trim configurations is available, depending on the planned service condition:

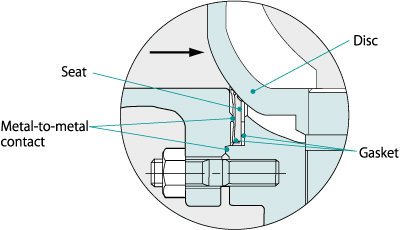

FLEKSEAT, made of spring Steel Type 316, provides elasticity in its contact with the hard-chromium plated CF8M disc for higher sealing performance. This seat is recommended for pulp and paper mill process control and services where higher sealing performance is critically required on valve shut-off.

This seat is suited for throttling service. (KITZ Fig. UVC)

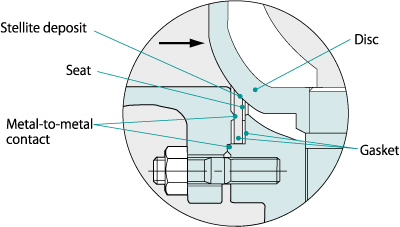

KNIFESEAT, made of Stellite deposited steel Type 316, contacts hard-chromium plated CF8M disc for heavy duty services. This seat is recommended for slurry service, and all other abrasion services. Also good for high viscosity services including pulp and paper mill processes.

It is also recommended for throttling service. (KITZ Fig. UVCT)

3. Structural reliability

Metal-to-metal contact is accommodated between body and cap, and between seat and cap, for correct seat centering and adequate depressing force. Spline shafted stem ends are firmly jointed with the disc for correct disc centering and higher operational durability. In addition, trunnion mounting of the disc on the body helps increase total structural reliability of the valve against extraordinary piping stress.

4. Stabilized operating torque

Metal backed PTFE stem bearings are employed on top and bottom stems for minimized and stabilized torque of valve operation. Fine finish of the disc surface and other sliding surfaces of components also helps smooth operation of the valve.

5. Maintenance ease

Two-Piece split body construction provides the convenience of easy maintenance which is always critically required for handling viscous or fibrous line fluids.

6. High flow efficiency

Full bore design guarantees maximized and linear flow characteristics with minimized pressure loss, helping viscous or fibrous line fluids pass through the valve bore smoothly.

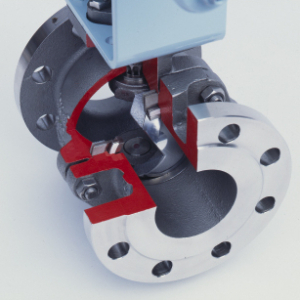

7. Valve automation

Quarter-turn valve drive mechanism enables technically easier mounting of valve automation measures such as electric and pneumatic actuators. Integral pads are provided for easy, safe and assured on-the-spot actuator mounting without disassembly of valve glands, as required by ISO standard.

Note: Customers are requested to prepare mounting brackets and connectors chosen for their valve actuation as illustrated here.

Caution: KITZ Λ-port® control valves are designed for unidirectional flow control. Be sure to mount the valve correctly so that the direction of line flow matches the direction of the arrow mark cast on the valve body.

Registering E-mail Magazine

We will send support information, new product information, and application information for our users.