Floating Ball valve covers wide range of application such as Power, Natural Gas pipe line, Petro-chemical, Chemical plant, factory and building construction

- Product Service TOP

- List of Products and Services

- Butterfly Valves and Ball Valves

- Floating type ball valve (General flange type)

Floating type ball valve (General flange type)

FEATURE ( Seven safety consideration)

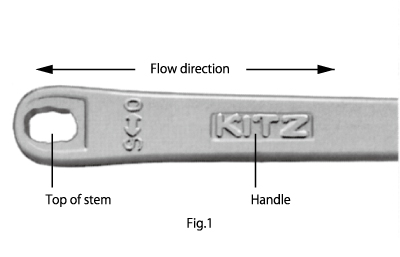

1. Double “D” stem head design provides mounting of the lever handle always in parallel to the flow passage. This feature prevents the lever handle from being installed in a wrong orientation. (Fig. 1)

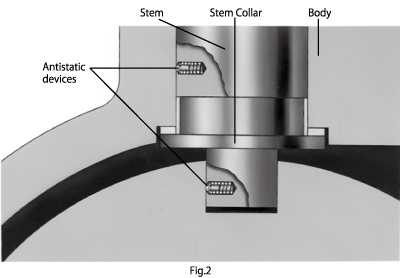

2. The lower end of the stem is designed with an integral collar to be blowout-proof. (Fig. 2)

3. An antistatic feature is provided to ensure electrical continuity between ball, stem, and body. (Fig. 2)

4. Facility for mounting a locking device for prevention of accidental valve operation is provided.

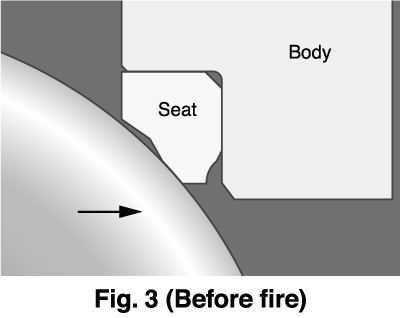

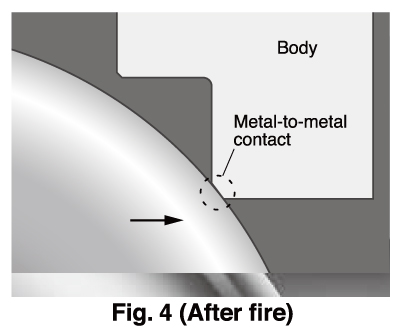

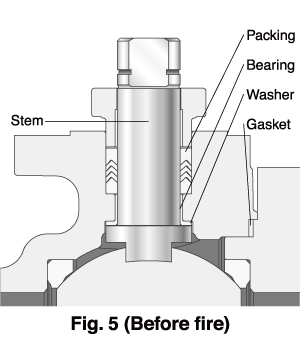

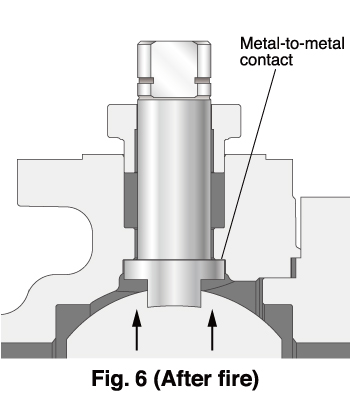

5. Plant fires are a serious concern for soft-seated ball valves because of possible fluid leakage by deterioration of resilient

sealing materials.

KITZ ball valves are engineered for fire-safety and successfully fire tested to minimize both external and internal fluid leakage after plant fires. They have post-fire metal-to-metal contact of all sealing areas such as:

■ Contact between ball and valve shell (Fig. 3 and 4)

■ Contact between stem and valve shell (Fig. 5 and 6)

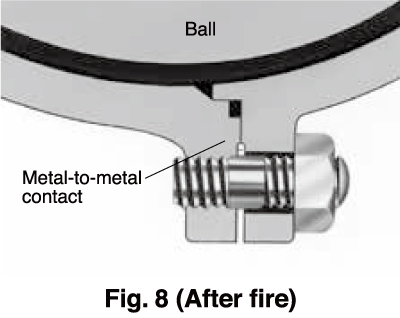

■ Valve shell coupling flanges of split body design (Fig. 7 and 8)

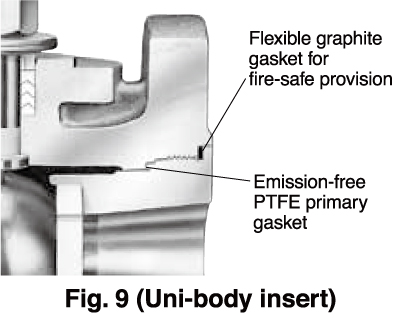

■ Contact between valve body and insert of uni-body design (Fig. 9)

The problem of external fluid leakage is more serious than internal leakage through the valve bore because of the fear of fueling the fire. To prevent this, KITZ ball valves may be ordered with flexible graphite packing and gaskets, which are extremely heat resistant, and not affected by the fire.

6. The surface of stem and stuffing box, and interface clearance of stem-to-gland, stem-to-body and gland-to-stuffing box are precisely controlled on machining and assembly for low emission service.

A Belleville spring washer is employed for live loading on gland bolts, to minimize need of retightening the bolts for low emission service.

7. Some line fluid is usually left trapped inside the ball-body cavity. This fluid can expand under the influence of high ambient or line temperature. An excessive cavity pressure rise may sometimes damage the valve seats or balls, unless the valve has an adequate cavity pressure relief mechanism. Trunnion mounted ball valves generally provide perfect protection from this problem. Please contact KITZ Corporation for details.

In case of floating ball valves, however, their rather simple seating principle requires some special protection from excessive cavity pressure rise when highly volatile liquid in service is subject to frequent and large temperature variation, while the valve is not frequently operated. KITZ 150/300 SCTDZ/UTDZ(M) and 150/300 SCTAZ/UTAZ(M) Series ball valves offer self-relieving of excessive cavity pressure as a standard feature engineered in HYPATITE® PTFE ball seats.

Other general solutions for floating ball valves include employment of automatic pressure relief valves or drilling pressure equalization holes on the ball. If the requirement of automatic cavity pressure relief is as critical as in chlorine service, be sure to contact KITZ Corporation or its distributors for technical advice.

This capability is influenced by many variables including: fluid characteristics, variations in pressure, temperature and thermal cycles.

Registering E-mail Magazine

We will send support information, new product information, and application information for our users.