KITZ ball valves are furnished, as the manufacturer’s standard, with HYPATITE® PTFE ball seats made of denatured PTFE, a molecularly reinforced PTFE copolymer, and specially engineered for high performance which include:

Ball seats

The following seat materials are available.

| Material | Features | Maximum Service Temperature |

|---|---|---|

| Virgin PTFE | High chemical resistance and operation efficiency | 200℃ |

| HYPATITE® PTFE | Monomer permeability is lower and resistance against compression and creeping is higher than other PTFE materials | 260℃/270℃*1 |

| Carbon filled PTFE | Excellent heat and abrasion resistance | 260℃/270℃*1 |

| FILLTITE®* | Highest heat resistance among PTFE based materials | 300℃*2 |

| Graphite | Excellent for high temperature service | 500℃ |

| Metal | Excellent for high temperature and abrasive service | 500℃/525℃*3 |

| PEEK | Higher heat resistance and mechanical strength | 270℃ |

| Glass fiber filled PTFE with MoS2 | Higher abrasion resistance and operation efficiency | 230℃ |

| Nylon with MoS2 | Higher mechanical strength | 140℃ |

* FILLTITE® is a specially reinforced ball seat, made by using more carbon based fillers into PTFE than conventional carbon filled PTFE, which greatly improves heat and abrasion resistance. The material shows excellent operability, durability, chemical resistance and sealing performance at a high temperature of 300℃. In addition, the ball seat is interchangeable with the most of our conventional ball seats, so it also has the cost

advantage.

*1 270℃: SCTDZ/UTDZM Series only.

*2 Uni-body design: 260℃

*3 525℃: T60M/SF3TC 6H UF3TC6HM Series only.

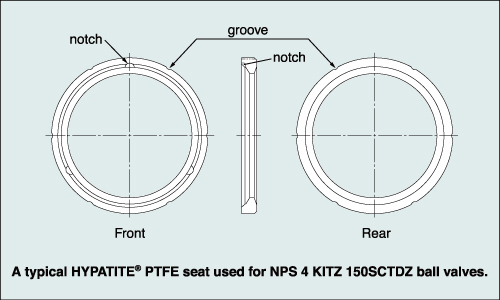

HYPATITE® PTFE Ball Seats (Carbon and Stainless Steel Valves)

- Wide service temperature range of −29°C (-20°F) through 270°C (518°F) SCTDZ/UTDZ(M) Series, 260°C (500°F) UTB and SCTAZ/UTAZ(M) Series.

This is for standard valve design and materials used for medium to high temperature services. The lower temperature range can be extended down to −196°C (-321°F) by means of extended bonnet design and special low temperature service materials. - High chemical resistance comparable to virgin PTFE.

- Monomer permeability lower than other PTFE materials.

- High mechanical strength against compression and creeping (cold flow), superior to other PTFE materials for long life cycle.

- Smooth operation, as it possesses specific gravity and friction coefficient equal to those of virgin PTFE.

- Prevention of contamination for process line because of its stability, the performance comparable to virgin PTFE.

- High sealing performance brought by its resiliency, the typical feature of PTFE.

FILLTITE® Ball Seats

Highest heat resistance among PTFE based materials.

- Service temperature range: -29°C to 300°C

- Trim symbol: 1H

Technical Data

1. Choice of trim for heated abrasive service

Metal seated ball valves are guaranteed for a maximum service temperature of 300°C (572°F) (Trim symbol 5H) and 500°C (932°F) (Trim symbol 6H*1*2). For hard graphite seated ball valves, a maximum service temperature of 500°C (932°F) is also guaranteed (Trim symbol 3H*2). Heat resistant sealing and trim materials qualify these valves for heated and abrasive service which cannot be properly handled by conventional soft seated ball valves due to the limited heat resistant characteristics and mechanical properties of their soft seats.

“FILLTITE®” is a specially reinforced ball seat, made by using more carbon based fillers into PTFE than conventional carbon filled PTFE, which greatly improves heat and abrasion resistance. The material shows excellent operability, durability, chemical resistance and sealing performance at a high temperature of 300°C. In addition, the ball seat is interchangeable with the most of our conventional ball seats, so it also has the cost advantage.

*1 Temperature is limited to 450°C (842°F) for trunnion mounted ball valves with trim 6H

*2 Shell material WCB: Upon prolonged exposure to temperatures above 425°C (797°F), the carbide phase of steel may be converted to graphite.

Permissible, but not recommended for prolonged usage above 425°C (797°F).

2. Unconditional fire-safe provision

While metal or hard graphite seats are extremely heat resistant, other sealing components such as gland packing and flange gaskets are made of flexible graphite, another heat resistant material, so that no part of the valve will be affected by extraordinarily heated environments. Also the provision of an anti-static device is not required because of inter-component electric conductivity.

3. Maintenance ease

Split body construction of the valve body provides the convenience of easy maintenance, a critical requirement for handling slurries and other viscous fluids.

4. Valve automation

Quarter-turn valve drive mechanism makes mounting of valve automation measures such as electric and pneumatic actuators technically easier. KITZ floating ball valves employ integral actuator mounting pads, complying with ISO 5211 and CAPI, for easy, safe and assured on-the-spot actuator mounting without disassembly of valve glands.

5. High flow efficiency

Full port design provides maximized and linear flow characteristic with minimal pressure loss as the line flow travels through the valve bore. This is a necessary design requirement particularly for trouble-free service of

slurries and other viscous fluids.

6. FILLTITE® seated ball valves (Trim1H)

Highest heat resistance among PTFE based materials.

| Valve Design | Floating Ball Valve | Trunnion Mounted Ball Valve |

|---|---|---|

| Trim symbol | 1H | |

| Temp. | 300°C | |

| 572°F | ||

| Parts | Ball | ASTM A276 Type 304*1 or A351 Gr.CF8*1 |

| Ball seat | FILLTITE® PTFE | |

| Stem | ASTM A276 Type 304*2 ASTM A276 Type 316*2 |

|

*1 Shell material CF8M; Ball Type 316 or CF8M

*2 Shell material CF8M; Stem Type 316

7. Hard graphite seated ball valves (Trim 3H)

- Bi-directional flow.

- Recommended for low abrasion service.

| Valve Design | Floating Ball Valve | |

|---|---|---|

| Trim symbol | 3H*5 | |

| Temp. | 500°C | |

| Seat leakage*1 | 932°F | |

| Parts | Ball | ANSI FCI 70-2 Class Ⅵ |

| Type 304*1 or A351 Gr.CF8*2 | ||

| Ball seat | Carbon + JIS SUS329J1*3 | |

| Stem | ASTM A276 Type 304*4 | |

*1 Maximum allowable seat leakage *2 Shell material CF8M; Ball Type 316 or CF8M

*3 Equivalent to AISI Type 329 *4 Shell material CF8M; Stem Type 316

*5 Shell material WCB: Upon prolonged exposure to temperatures above 425°C (797°F), the carbide phase of steel may be converted to graphite. Permissible, but not recommended for prolonged usage above 425°C (797°F).

Caution:

- Not recommended for throttling service.

- Not recommended for high abrasion service.

- Maximum working temperature for oxidizing service, such as high temperature air, is 450°C (842°F).

8. Metal seated ball valves (Trim 5H/6H)

Rigid construction with full metallic contact between the ball and seats, and high durability of trim materials make KITZ metal seated

ball valves ideally suited to highly abrasive services handling slurries and other viscous fluids.

Trim materials

| Valve Design | Floating Ball Valve | Trunnion Mounted Ball Valve | |||

|---|---|---|---|---|---|

| Split body | 3-piece body | ||||

| Trim symbol | 5H | 6H *3 | 6H | ||

| Temp. | 300°C | 500°C | 450°C | 525°C | |

| 572°F | 932°F | 842°F | 977°F | ||

| Seat leakage*1 | ANSI FCI 70-2 Class Ⅵ | ISO 5208 RateD/ANSI FCI 70-2 Class Ⅵ *4 | |||

| Parts | Ball | ASTM A276 Type 316 or ASTM A351 CF8M + Cr plated |

ASTM A276 Type 316 or A351 Gr.CF8M + SFNi *2 |

ASTM A276 Type 304 + SFNi *2 | 316 Stainless steel + SFNi *2 |

| Ball seat | ASTM A276 Type 316 + SFNi *2 | ASTM A276 Type 316 + SFNi *2 | ASTM A276 Type304 + SFNi *2 | 316 Stainless steel + SFNi *2 | |

| Stem | ASTM A 564 Type 630 | ASTM A 564 Type 630 | ASTM A276 Type304 + SFNi *2 | ~343°C/649°F : ASTM A564 Type630 ~525°C/977°F : EN 1.4980 |

|

*1 Maximum allowable seat leakage *2 Ni-Cr alloy thermal spraying

*3 Shell material WCB: Upon prolonged exposure to temperatures above 425°C (797°F), the carbide phase of steel may be converted to graphite.

Permissible, but not recommended for prolonged usage above 425°C (797°F).

*4 Please contact your local KITZ agents or distributors.

- Durable metal seat design and material also provides fully guaranteed throttling service performance, which makes KITZ metal seated ball valves function as a reliable control valve.

- Bi-directional flow.

Caution:

- Use a gear operator or valve actuator to fix the valve position when used for throttling service.

Registering E-mail Magazine

We will send support information, new product information, and application information for our users.